Products

Protection and Safety with d-flexx Technology

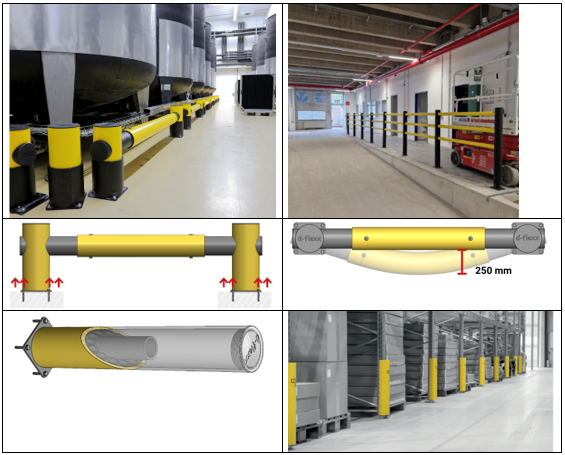

In its commitment to offering innovative industrial safety solutions, REAM presents products designed to protect people, equipment, inventory and structures against impacts in industrial environments.

The d-flexx safety barriers, made from high-quality flexible polymers, stand out for:

- Impact Absorption: Capable of absorbing up to 80% of the energy generated by impacts, minimizing damage to surfaces and equipment.

- Durability and Adaptability: Designed to withstand extreme temperatures (-40°C to +50°C) and ensure UV stability in both indoor and outdoor applications.

- Compliance with Standards: TÜV Nord certification and design aligned with PAS 13 standards, ensuring maximum quality and safety.

In addition, its modular systems offer customizable solutions, adapting to the specific needs of each client. Thanks to advanced tools such as the "d-flexx Designer," the planning and execution of security projects are carried out with precision and efficiency.

REAM, your trusted partner in optimizing industrial safety with cutting-edge d-flexx technology.

Advantages of d-flexx barriers over steel barriers

1.Superior Impact Absorption

- They absorb up to 80% of the energy generated by impacts

- Steel barriers, not having the capacity to bend, transfer the impact energy directly to the installation point, causing greater damage.

2.Reduction of Repair Costs

- o d-flexx barriers return to their original shape after impact, minimizing the need for replacement or repair.

- Steel barriers often deform or break after impact, resulting in high maintenance costs.

3.Floor Protection

- d-flexx barriers are designed to protect concrete floors, thanks to their buffer pipe technology, which reduces energy transfer to the anchor point.

- Steel barriers can cause cracks or structural damage to floors due to their rigidity.

4.Durability and Resistance to Extreme Conditions

- d-flexx barriers are resistant to extreme temperatures (-40°C to +50°C) and UV exposure, making them ideal for indoor and outdoor environments.

- Steel barriers are prone to rust or deterioration in adverse weather conditions.

5.Modularity and Flexibility

- d-flexx systems are highly modular, allowing for custom configurations and rapid adaptations with minimal tooling.

- Steel barriers often require predefined designs, limiting adaptability and increasing installation time.

6.Compliance with Standards and Certified Safety

- d-flexx barriers are certified by TÜV Nord and comply with PAS 13 standards, ensuring their performance and safety.

- Steel barriers may not meet modern safety standards in all applications.

7.Lower Environmental Impact

- d-flexx polymers are lighter and require less energy for transportation and installation, as well as being easier to recycle.

- Steel barriers are heavier, more expensive to transport and have a greater environmental impact over their life cycle.