Products

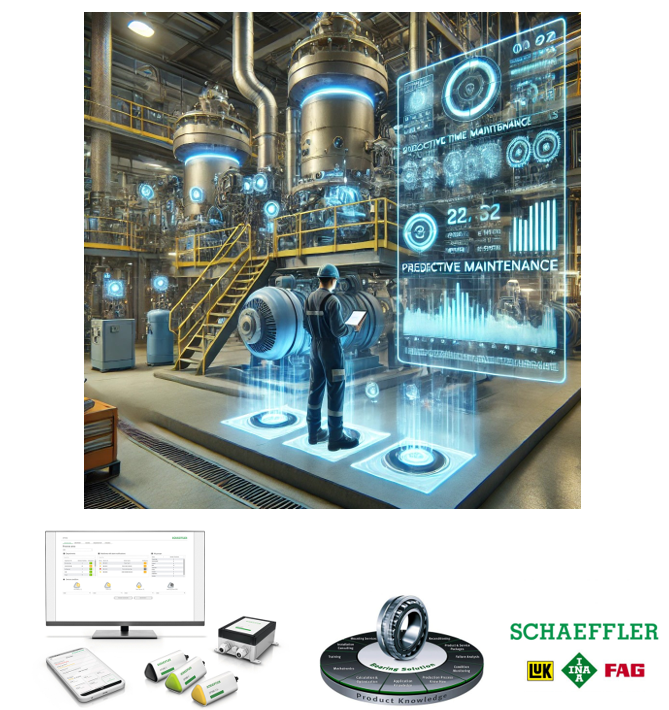

Condition Monitoring

The MonCon system is designed for continuous, real-time monitoring of the conditions of industrial equipment and systems. This equipment uses advanced technologies such as high-precision sensors, vibration analysis, temperature, and other critical variables to detect potential failures before they occur.

With MonCon, companies can implement condition-based maintenance (CBM) strategies, increasing reliability, reducing operating costs and improving asset availability.

Main Features:

- Early fault detection: Analyze critical data to prevent unexpected downtime.

- Technological integration: Compatible with IoT systems and predictive analysis platforms.

- Customization: Configurable to suit specific requirements of different industries.

- Sustainability: Reduces energy waste and optimizes the use of resources.

Advantages of MonCon Equipment

1.Reduction of unplanned downtime:

- Detect early failures before they become critical problems, minimizing unexpected production downtime.

2.Increased equipment reliability and availability:

- Improve operational performance by ensuring equipment runs optimally for longer.

3.Operating cost optimization:

- Implement condition-based maintenance (CBM), reducing unnecessary spending on excessive corrective or preventive maintenance.

4.Better decision making:

- Provides real-time data and detailed analysis to plan maintenance strategies more accurately.

5.Compatibility with emerging technologies:

- Integration with IoT systems, Big Data and predictive analytics platforms for an intelligent industrial ecosystem.

6. Personalization and adaptability:

- Configurable for different types of industries and equipment, ensuring tailor-made solutions according to specific needs.

7.Sustainability and energy efficiency:

- Helps reduce unnecessary energy and resource consumption by optimizing asset performance.

8.Compliance with industrial safety standards:

- Ensures safe operations, protecting both equipment and personnel.

Condition Monitoring (MonCon) equipment typically includes technologies and devices that enable continuous or periodic analysis of equipment status, with the goal of identifying potential failures before they occur. This equipment typically falls into the following categories:

1.Sensors:

- Vibration sensors: To detect imbalances, misalignments, mechanical clearances, etc.

- Temperature Sensors: Useful for motors, bearings, transformers and more.

- Pressure sensors: For hydraulic or pneumatic systems.

- Ultrasonic sensors: To identify air or gas leaks or bearing defects.

- Current and voltage sensors: For monitoring electrical parameters in motors and electrical systems.

2.Portable Analyzers:

- Vibration analyzers.

- Portable ultrasound detectors.

- Thermal imaging cameras: For thermal analysis of equipment.

- Oil analysis equipment: For monitoring particles and viscosity in lubricants.

3.Online Diagnostic Equipment

- • SCADA systems integrated with monitoring sensors.

- • IoT equipment with wireless communication for remote analysis.

- • Continuous monitoring devices for turbines, motors and pumps.

4.Monitoring and Diagnostic Software

- Predictive analysis tools based on Machine Learning.

- Remote monitoring platforms with intuitive dashboards.

- Integrations with ERP or CMMS to plan maintenance.

Other Accessories and Tools

- Laser tachometers for measuring rotational speed.

- Laser alignment measurement equipment.

- Particle detectors for hydraulic systems.

At the forefront of Schaeffler technology. Bearings; wireless and wired vibration sensors, specific analysis software, automatic lubricants; much more

At the forefront of Schaeffler technology. Bearings; wireless and wired vibration sensors, specific analysis software, automatic lubricants; much more